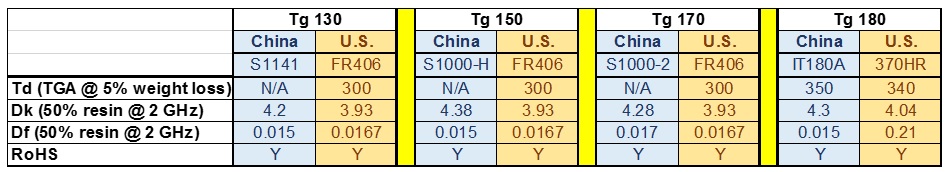

These laminates offer significantly improved electrical performance over standard fr4 and often a combination of fr4 and a high speed laminate may be preferable to an alternative fr4 material.

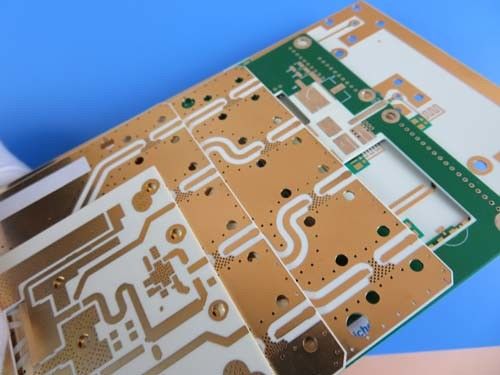

Thin pcb laminate.

Rigid 0 020 n5105 laminate part number.

N5305 nelco n5000 bt epoxy laminate and prepreg pcb materials provide superior electrical properties.

Sytech is a world leader in the development and production of laminates.

Thin fr4 boards can t feasibly feature grooves and they can t be too large without risking fracture.

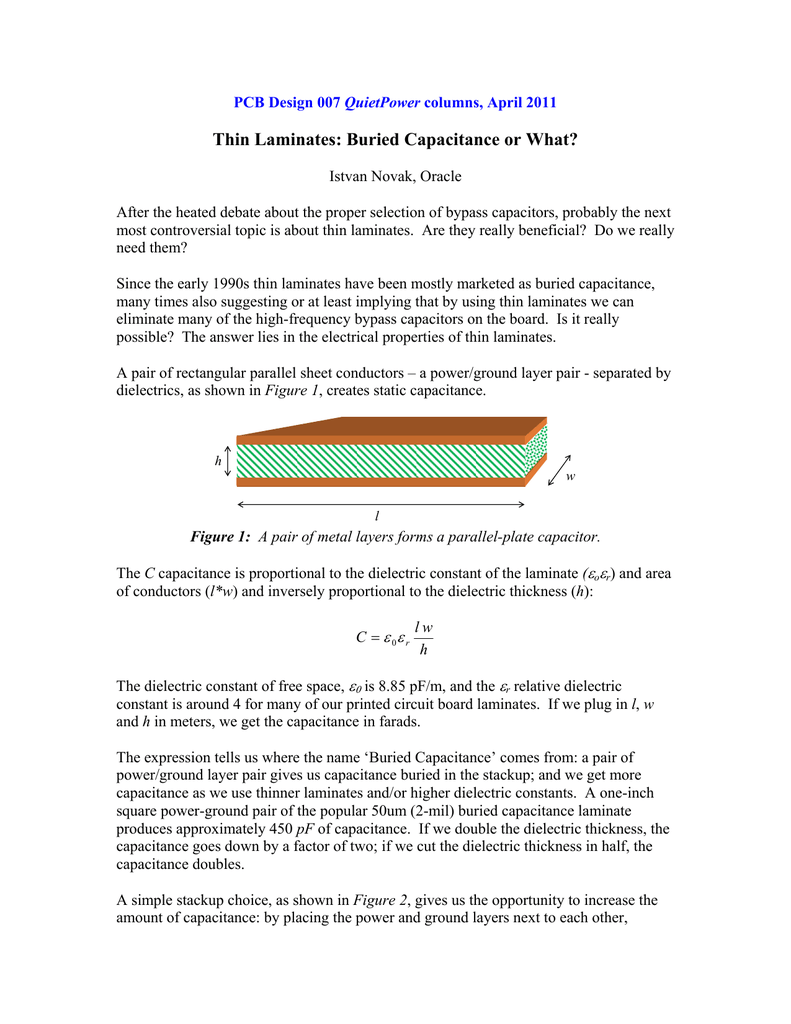

Thin pcb laminates for power distribution how thin is thin enough.

So when it comes to thin laminates think about their inductance rather their capacitance.

Zeta cap a glass free laminate produced by integral technology has received us patent no.

The n5000 resin system was originally developed for application specific use in high density military.

Sisler method of making multilayer printed circuit board us patent 5 010 641 april 30 1991.

Bt epoxy laminate and prepreg laminate part number.

Fr4 tends to have higher losses than other printed circuit board pcb materials that are specialized for rf applications.

Zeta cap ultra thin high performance pcb cap material description.

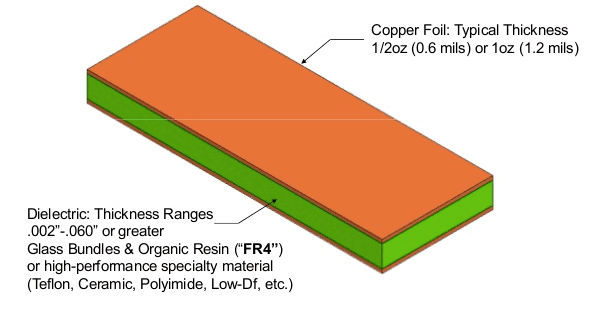

Thin can be a good thing for high frequency circuit laminate materials.

Cyr sun microsystems inc bob greenlee merix corporation john grebenkemper compaq computer corporation jason gretton aromat corporation a matsushita company.

They offer the best mechanical strength reliability and capacitance stability on the market.

The company maintains a high commitment to on going r d efforts and provides a complete portfolio of products ranging from composites to high reliability thermal management hsd and rf ptfe laminate materials.

Thin boards aren t preferable in all cases primarily due to the limitations thin boards put on pcb plans.

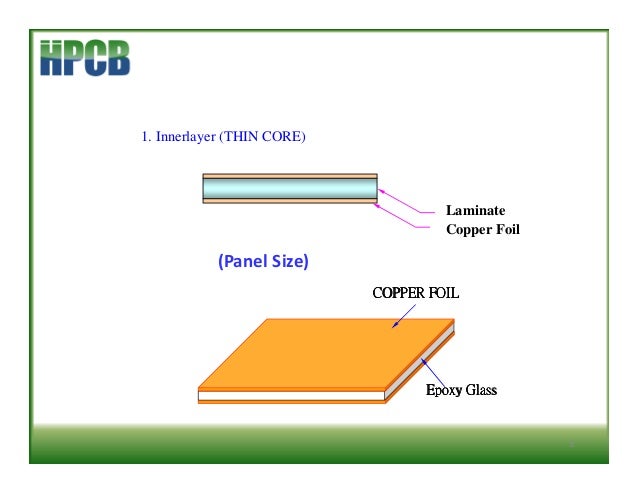

Dupont interra thin copper clad laminates are specifically designed for use as embedded capacitance materials in multilayer rigid printed circuit boards.

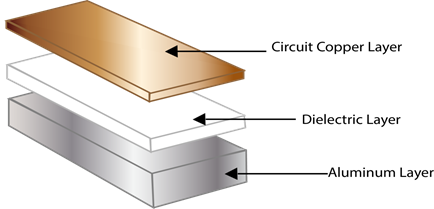

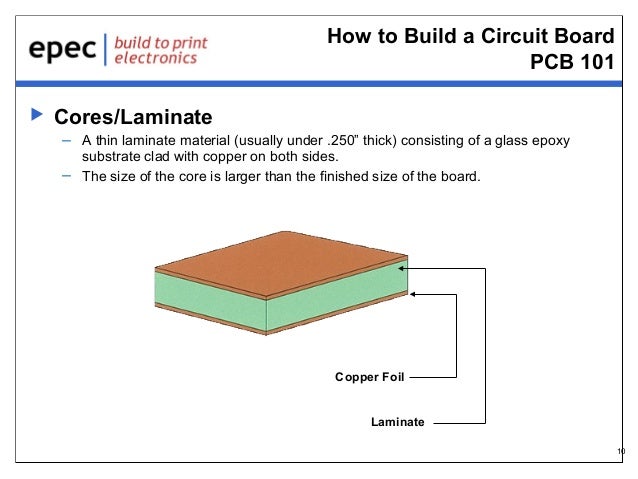

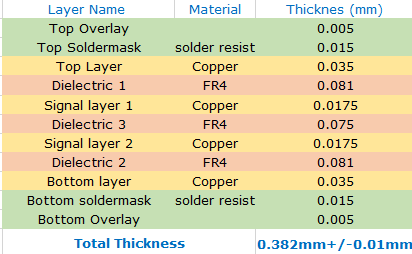

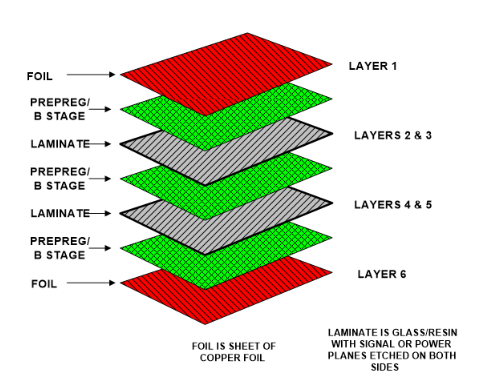

Printed circuit boards pcbs are usually a flat laminated composite made from non conductive substrate materials with layers of copper circuitry buried internally or on the external surfaces.

The patent was filed as an improved insulating layer for rigid printed circuit boards.

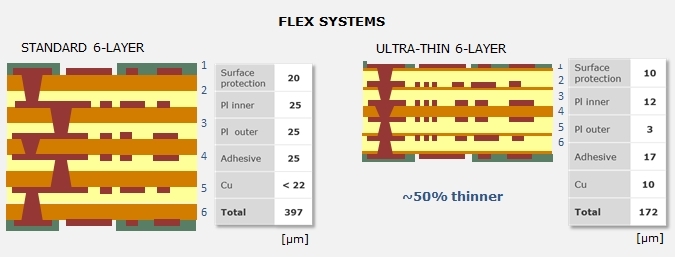

They can be as simple as one or two layers of copper or in high density applications they can have fifty layers or more.

As this blog detailed some years ago thinner printed circuit board pcb laminates offer many electrical benefits as well as mechanical advantages compared to thicker circuit materials especially at higher frequencies reaching into millimeter wave bands.

Matters is the inductance and thin laminates create very low inductance indeed.

Interra thin copper clad laminates for embedded capacitance.

Thicker boards however can accomplish both.

Always account for this when weighing options between fr4 thicknesses.