It involves laying out sheets of copper on a roofing substrate that assembles in one piece without joints or seams.

Roofs made of sheet copper should be jointed with solder.

Alternative tin based solders are available for those who prefer a lead free installation.

As such the filler metals for soldering and brazing copper and copper alloy tube and fittings must have melting temperatures below this temperature.

The upstand would then be folded over either once or twice to form the seam.

The melting point of copper cu alloy uns c12200 is 1 981 f 1082 c.

Metal roof tiles are typically made of.

To do this solder is applied to the back or concealed edge of copper surfaces walas says.

Sheet copper roofs are jointed with.

Lap seams should have a minimum 1 inch overlap and no gaps larger than 1 16 inch.

Clips attached to the roof would be held between the sheets.

Make your seams tight clean clean and tight seams are essential.

The proper flux to use depends on the material you are soldering.

Solder much prefers bright copper with a very close fit.

The higher the tin content in the solder the higher the tensile shear strength will be.

The solder often used is common 50 50 tin lead bar solder for uncoated copper.

Standing seams or solder.

Fasteners made of are recommended for tile roofs.

Protects the roof from sunlight.

A steel roof and an aluminum vent are a bad match because of.

Continuous copper roofing is the most expensive option.

Sheet copper roofs are jointed with.

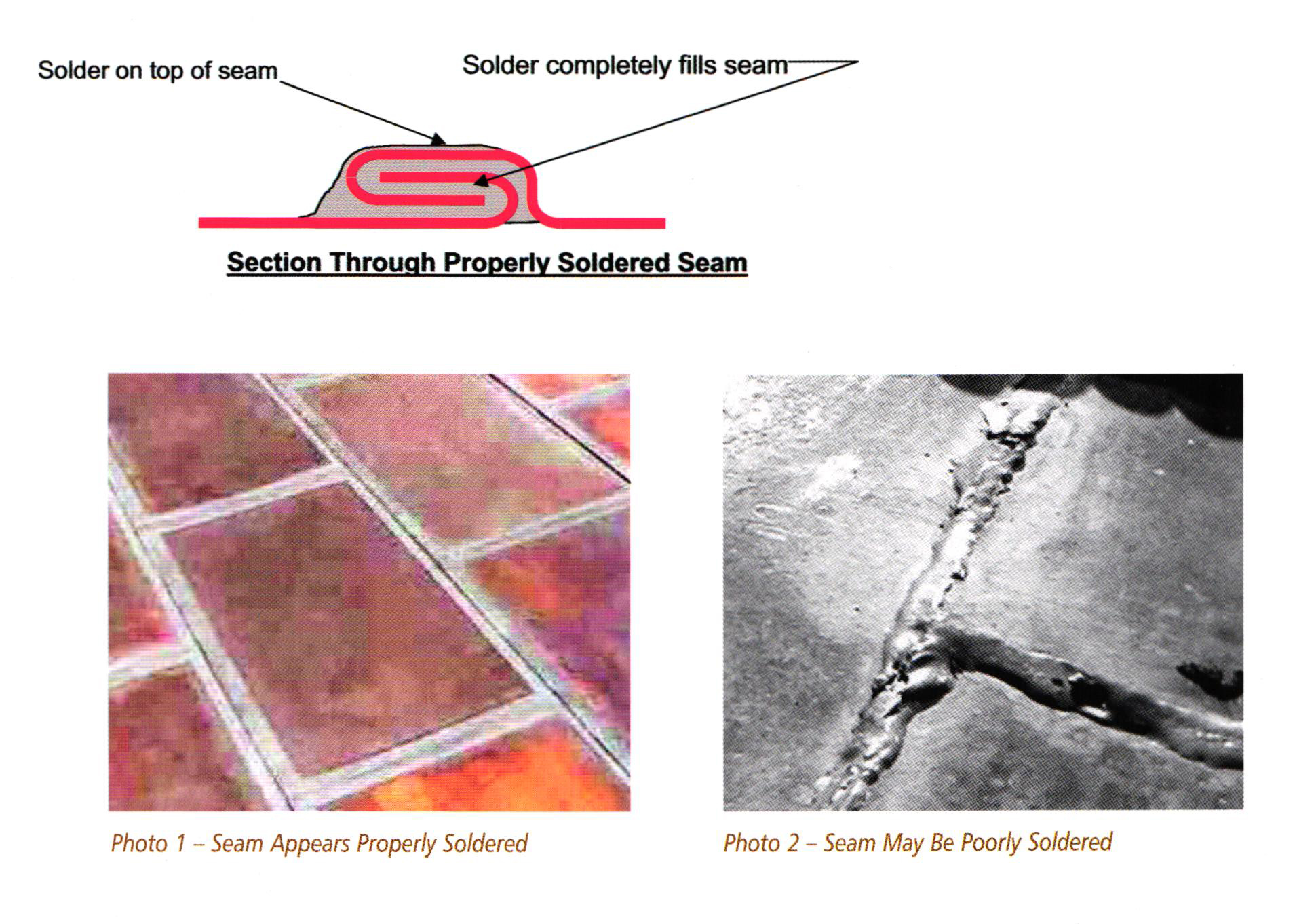

Architectural sheet metal components such as flat seam roofing and flashings must be joined properly to maintain durable and reliable watertight assemblies photo 1.

Horizontal joints would be folded over flat to form welts.

Continuous long runs of soldered seams should be avoided to limit stress fractures lead free options which are primarily tin based are available for lead.

Lead coated copper should be soldered with 60 40 lead tin solder.

Blind soldering minimizes exposed solder in finished joints.

This is a specialty application generally designed and prefabricated for an exact job.

Lead coated copper does not extend the life of copper.

Panels are less expensive than continuous.

Soldering flux serves one main function in joining roofing materials it is meant to prevent oxidation of the metal which causes poor adherence of solder.

Install only as much copper as can be soldered by the end of the day.

Lead coated copper will benefit from the added strength of using a 60 40 lead tin solder.

A steel roof and an aluminum vent are a bad match because of.

Until 1870 nearly all copper sheet roofing was laid in sheets generally 2 by 6 in size joined at the sides with vertical standing seams.

While sealants can provide watertight integrity on steep sloped applications the relatively short service life.

Standing seams or solder.

Copper or stainless steel.

Crushed stone or gravel ballast on a built up roof.

Metal roof tiles are typically made of.